Background

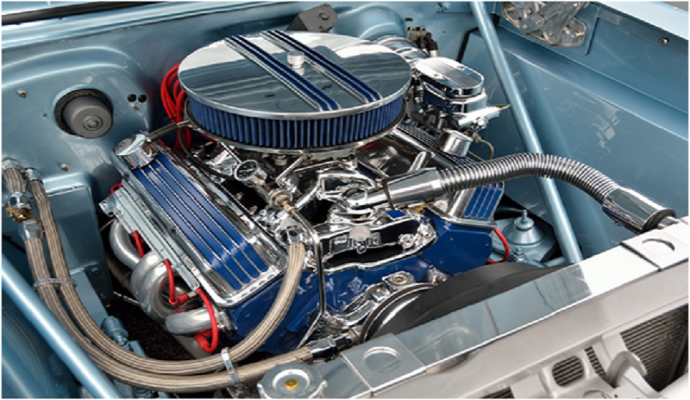

An automotive manufacturer was keen to upgrade its engine shop by investing in automation with a built-in mistake proofing system. They were seeking significant cost reductions and quality improvements through process automation.

Implementation

- Assisted in designing newly automated line with poka-yoke system

- Used Simodrive (Profibus DP and Profinet Communication)

- Stations automated with Siemens S7-400 PLC system

Outcome

- Significant productivity improvements

- Ensured consistent quality

- Flexibility to upgrade with minimum shutdown time